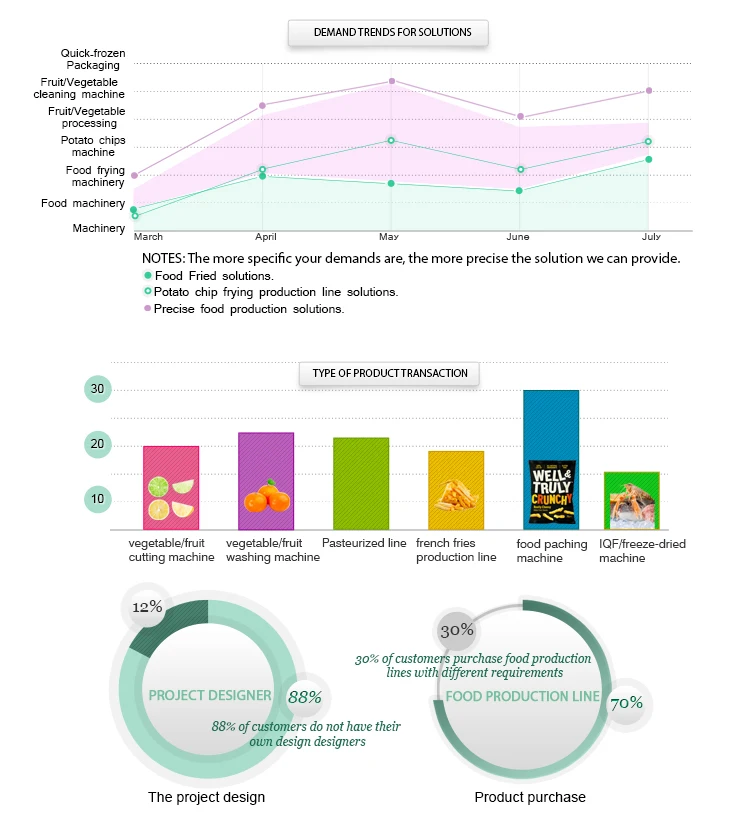

french fries potato chips production line

Plantain Cassava Banana Chips Frying Making Machine Production Process Line Price

7.The size of French fries and the thickness of potato chips are adjusted.

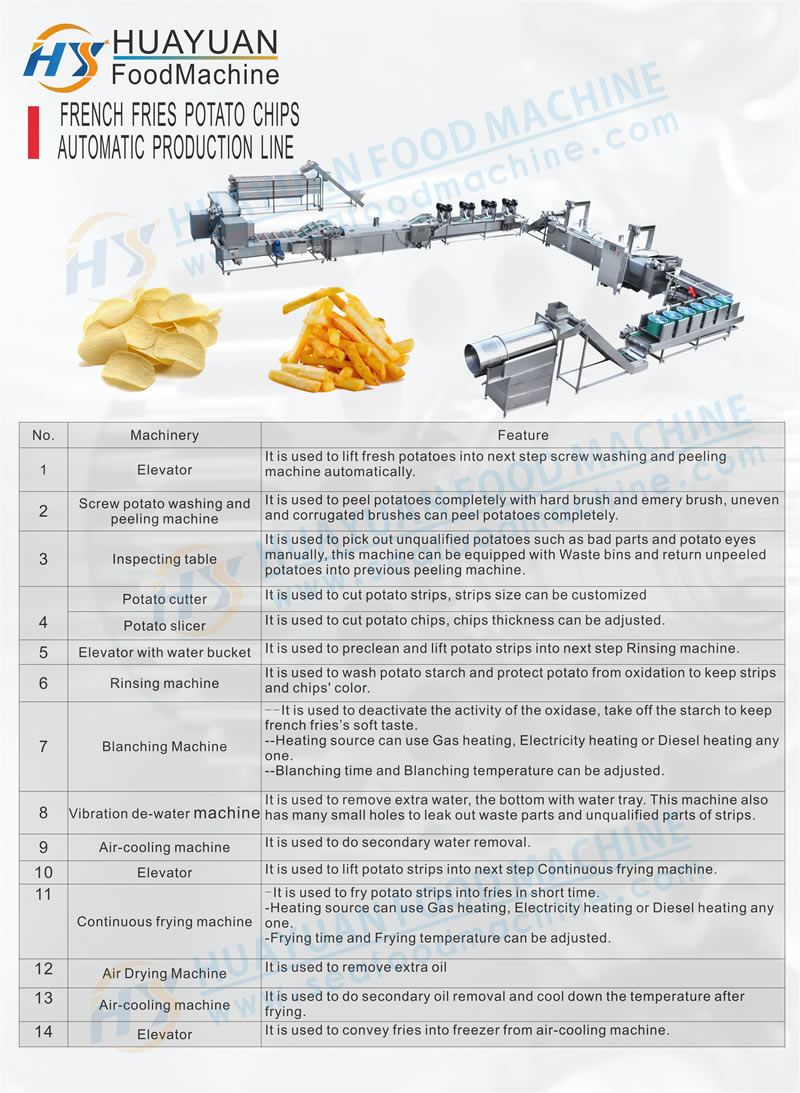

| No. | Name | Quantity | Dimension | Power | Net weight |

| 1 | Conveyor hoist machine | 1 set | 2000*800*2000mm | 0.75kw | 200kg |

| 2 | Cleaning and peeling machine | 1 set | 1800*900*1500mm | 4.75kw | 620kg |

| 3 | Picking line | 1 set | 3000*900*900mm | 0.75kw | 300kg |

| 4 | French fries potato chip machine | 1 set | 950*800*950mm | 1.5kw | 110kg |

| 5 | Washing machine | 1 set | 3000*1600*900mm | 5kw | 800kg |

| 6 | Blanching machine | 1 set | 3000*1600*950mm | 2.2kw | 1000kg |

| 7 | Vibration water remover machine | 1 set | 1500*1000*1300mm | 15kw | 700kg |

| 8 | Picking line | 1 set | 3000*800*1000mm | 0.75kw | 300kg |

| 9 | Air cooled dewatering machine | 1 set | 4000*1200*1400mm | 15kw | 700kg |

| 10 | Conveyor hoist machine | 1 set | 2000*800*1300mm | 0.75kw | 200kg |

| 11 | Electric heating frying line | 1 set | 3500*1200*2600mm | 0.5kw | 2200kg |

| 12 | Vibration oil remover machine | 1 set | 1500*1000*1300mm | 1.5kw | 2200kg |

| 13 | Air drying machine | 1 set | 4000*1200*1600mm | 15kw | 700kg |

| 14 | Conveyor hoist machine | 1 set | 2000*800*2200mm | 0.75kw | 200kg |

| 15 | Seasoning machine | 1 set | 2000*700*1600mm | 1.5kw | 400kg |

| 16 | Packing Machie | 1 set | 2400*700*3200mm | 1.0kw | 400kg |

Our factory supports the customization of production planning scheme. We can design the application scheme diagram of product workshop for free. | |||||

Email:Sale@frenchfriesline.com | Wechat:+86 15249634567 | WhatsApp:+86 15249634567 | |||

|  |

| High pressure spray | Vibration dewatering machine |

|  |

| Vibrating dewatering screen | Water circulation storage tank |

Such as:

Fully Automatic Frozen Fried French Fries Production Line Potatoes Making Machines;

Industrial frozen fries line production potato chips making machine line;

Snack equipment potato and banana chips machine chips processing line;

Stainless steel 100kg potato chips making machine french fries production line;

Automatic french fries processing machine french fries production line;

Full Automatic Frozen French Fries Production Line with One Whole Control Panel;

Factory offer free machine workflow design industrial potato chips production line;

electric heating and gas heating automatic frozen potato chips french fries production line;

industrial for food factory use automatic french fried potatoes production line;

Featured Product 500 kg/h Full Automatic Frozen French Fries Production Line;

Zhengzhou Zhiyin Industrial Co., LTD is a professional manufacturer integrating meat processing equipment and vegetable cleaning equipment production and sales, has formed a set of raw material supply, product development, process design, finished product inspection, production and operation, storage and transportation, technical services as one of the perfect operating system.

Mainly engaged in sandwich pot series, cooking pot series, mixing pot series, meat processing equipment, vegetable cleaning equipment. The company has advanced processing center, laser cutting equipment, shear plate bending equipment and a full set of testing equipment. The main products are: sandwich pot, cold powder machine, rolling kneading machine, chopping and mixing machine, mixing stuffing machine, meat mincer, enema machine, vegetable cleaning machine, desalination machine, pasteurization machine, vibrating screen, flexible packaging blow-dry machine, etc.

Our company focuses on the production and processing of food machinery, provides customized services according to the needs of different programs, and develops long-term services and cooperation with Europe, Asia, South America and other regions and countries.

Email: Sale@Frenchfriesline.com

Wechat/WhatsApp:+86 15249674563

1. Why do you choose Zhiyin Food Machinery?

We have 9 years of production and development experience, high quality products, superior program design, good reputation has become the elements of the company.

2. Is the design scheme free of charge?

We design independent schemes free of charge according to customers' specific requirements, and design CAD drawings according to the actual application workshop.

3. Production cycle?

We design independent schemes free of charge according to customers' specific requirements, and design CAD drawings according to the actual application workshop.

4. After-sales service

We will guide the installation online and provide video and graphic information. If necessary, we will arrange technicians to install the machine on site. The after-sales service of the motors configured for our products is one year.